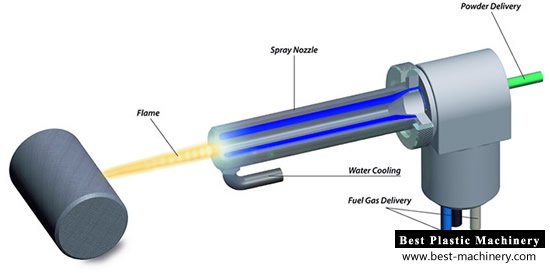

In the High Velocity Oxy-Fuel (HVOF) process, powder is introduced axially into a chamber in which a gas flame is constantly burning under high pressure. The exhaust gas exits through an expansion nozzle which produces a high velocity gas stream. The powder particles are heated in this gas stream and transferred by it with kinetic energy to the surface of the work piece, forming a dense coating with excellent bonding properties.

Due to the moderate transfer of heat to the powder particles and to the work piece, which remains relatively cool, there is little metallurgical change to either the sprayed material or work piece.